Direct Manufacturer AAC Brick Block Making Machine Price Central Asia

Package Size 300.00cm * 200.00cm * 210.00cm Package Gross Weight 3500.000kg AAC Block & Panel Production Line What is AA

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | aac machine |

| Customized | Customized |

| Automatic Grade | Automatic |

| Type | Aerated Autoclave |

| AAC Autoclave Steam Time | 8h |

| Steam Pressure | 1.3MPa |

| AAC Machine Required Person | 20 |

| AAC Machine Required Land | 10000m2-30000m2 |

| Material Mixing Time | 4-5min |

| AAC Line Working Ways | Total Automatic |

| AAC Green Block Cake Cutting Time | 4-5min |

| Temperature | 190degree |

| Productivity | 50000-600000m3 Per Year |

| Block Density | 400-700kg/M3 |

| AAC Block Size | 600X200X 75/100/200/240mm |

| AAC Capacity | 200000m3/Year, 250000m3/Year, 300000m3/Year |

| Mould Size | 600mm*200mm*75mm |

| Raw Material | Sand/Fly Ash, Cement, Powder Lime, Aluminium, Gyps |

| Porosity | Solid |

| Transport Package | Fit for Sea Transport |

| Specification | 600mm*200mm*75mm |

| Trademark | HF |

| Origin | Linyi Ity Shandong Province |

| HS Code | 8474802000 |

| Production Capacity | 880000m3/Year |

Packaging & Delivery

Package Size 300.00cm * 200.00cm * 210.00cm Package Gross Weight 3500.000kgProduct Description

Product Description |

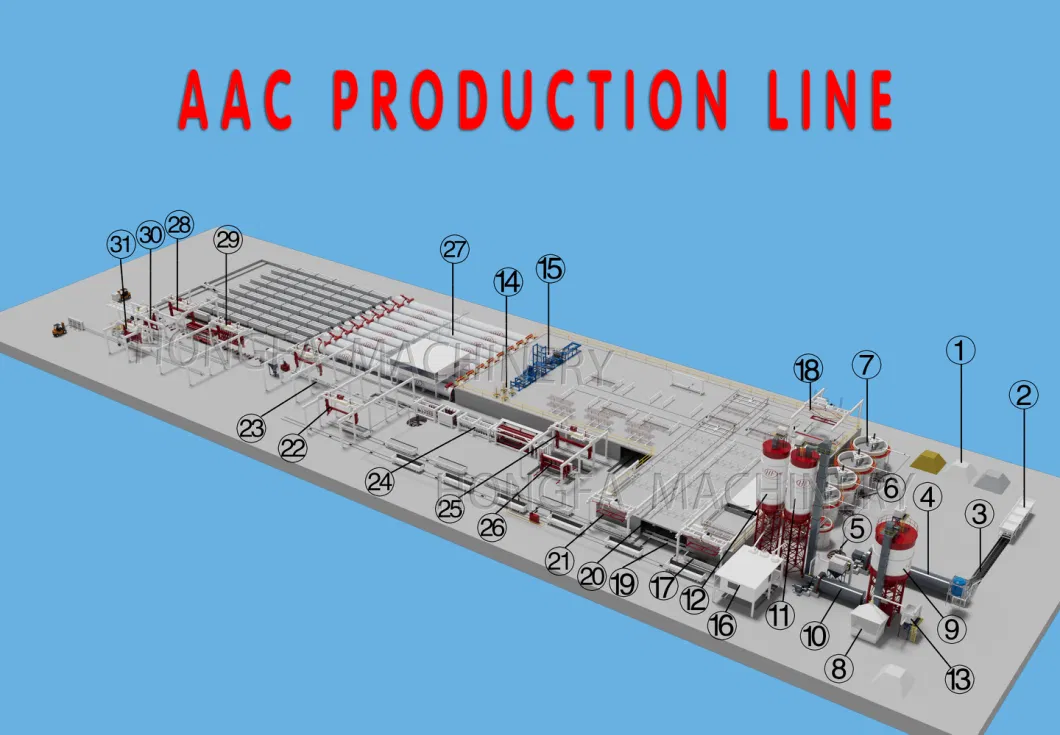

AAC Block & Panel Production Line

What is AAC ? AAC is the abbreviation of Autoclaved aerated concrete,It is a new type of light weight , thermal insulation building material .The raw material are siliceous materials (such as fly ash, sand) and calcareous materials (lime and cement) ,made by batching, pouring, expansion, cutting, curing and other processes.

Parameter of the processes

| Processes | Parameter |

| Mixing period | 5-6 minutes |

| Pouring slurry temperature | 40-45ºC |

| Cake curing time | 2.5-3.0h |

| Cake curing temperature | 45~55ºC |

| Cake strength after curing | 0.15~0.18MPa |

| Autoclaved curing system before-after autoclave | 0.5h |

| Vacuumize | 0.5h(0~-0.06MPa) |

| Listing pressure | 1.5h(-0.06~1.3MPa) |

| Constant pressure | 8h(1.3MPa) |

| Releasing pressure | 1.5h(1.3~0MPa) |

| total | 12h |

Gas block wall panel pictures and photos

| Raw Material Preparation1.Raw materials need to be ground before being processed. In order to meet the fineness requirements of the feed, block materials such as quicklime and natural gypsum need to be crushed.2.Grinding can give full play to the activity of the material;The ground slurry has better water retention and higher viscosity due to the dissolution of some components , which can make the slurry have proper consistency and liquidity |

| Material Batching and Pouring 1.Measure various raw materials, adjust the temperature and concentration, and feed materials to the mixing equipment in sequence according to the process requirements2.The pouring process is one of the unique processes that distinguish aerated concrete from other concretes. The prepared raw materials are stirred to meet the specified time temperature and consistency requirements to obtain slurry, then pour into the mold.3.Pouring and batching can be controlled separately or centrally, and different degrees of automation can be realized |

| Static Maintenance1.The poured mold is pushed into the resting room with a conveyor chain for initial gas generation and initial setting. The room temperature is 50-70°C, and the time is 1.5-2 hours.2.The resting process is mainly to promote the slurry to continue to complete the hardening process, so that the embryo body reaches a certain hardness for cutting |

| Cutting The cutting process is to divide and shape the AAC body to meet the appearance and size requirements. The cutting process reflects the characteristics of air-entrained concrete, which is convenient for large-volume molding, flexible and diverse in shape and size, and large-scale mechanized production |

| Autoclaving CuringThe autoclave curing process is to perform high-pressure steam curing on the cut aerated concrete body, and complete the hydrothermal reaction of CaO-SiO2-H2O in the kettle |

| Packing This is the last process of production, including pull out the finished products form kettle, lifting, inspection, packaging and cleaning and oiling of the bottom plate of the trolley |

Specification

Cutting Machine Group | Mold |

Somersault demoulding machine | Gas block Hoist: hoist block mould and grouping |

| Gas block Autoclave | Gas Slurry Pouring Mixer |

Packaging & Shipping

Our Factory |

office building

Our office building provides our staff with a comfortable working environment,thus we can keep improving our AAC machines and related service with higher productivity.

Customer plant |

We will arrange engineer to customer place installation , trainning workers.

FAQ |

A: One set;

Q:How long is warranty of AAC production line?

A: Electrical element 3 month, machine one year.

Q:How can I pay for my items? What is the payment you can provide of AAC production line?

A: T/T, 30% deposit payment, the balance will be paid after inspection and before shipment via T/T or L/C;

Q:what is the speed for handling complaints?

We understand that timely and effective handling of complaints is crucial to maintaining customer satisfaction. Our company is committed to responding promptly to any complaints received, and we have established an internal process to ensure that all complaints are handled in a timely and professional manner. Our goal is to address any issues and resolve them to our customers' satisfaction as quickly as possible.

Q:How about product quality and service assurance of AAC production line?

We are committed to providing high-quality products and services to our customers. To ensure that our products meet the highest standards, we conduct rigorous quality control tests and inspections throughout the production process. Additionally, we have a customer service team that is available to assist with any questions or concerns that customers may have, and we offer a satisfaction guarantee on all of our products.

Q: How about your local market share rate?

Our company is focused on building a strong presence in the local market. We are continuously monitoring market trends and adapting our strategies to stay competitive. We have a dedicated marketing team that is responsible for developing and executing effective marketing campaigns to increase our market share. We also prioritize building strong relationships with our customers and partners in the local market to foster long-term growth.

Q:How is your After-sales service of AAC production line:

We understand that the post-purchase experience is just as important as the initial sale. That's why we have a dedicated after-sales service team that is available to assist customers with any issues or questions they may have after making a purchase. Our team is trained to provide prompt and effective solutions to ensure that our customers are satisfied with their purchase and have a positive experience with our company.

Q:How about claims:

Our company takes claims seriously and we have established a clear process for handling them. If a customer has a claim, they can submit it through our website or by contacting our customer service team. We will review the claim and take appropriate action to resolve the issue. We strive to address claims promptly and fairly to ensure that our customers are satisfied with the outcome.

Q:How to deal the trade disputes caused by rising sea freight and others:

We understand that trade disputes can be disruptive to our business and we take steps to minimize their impact. We work closely with our suppliers and partners to ensure that we are aware of any potential issues that may arise. Additionally, we have a legal team that is well-versed in trade law and can provide guidance and support in the event of a dispute. We are committed to finding solutions that are fair and equitable for all parties involved.